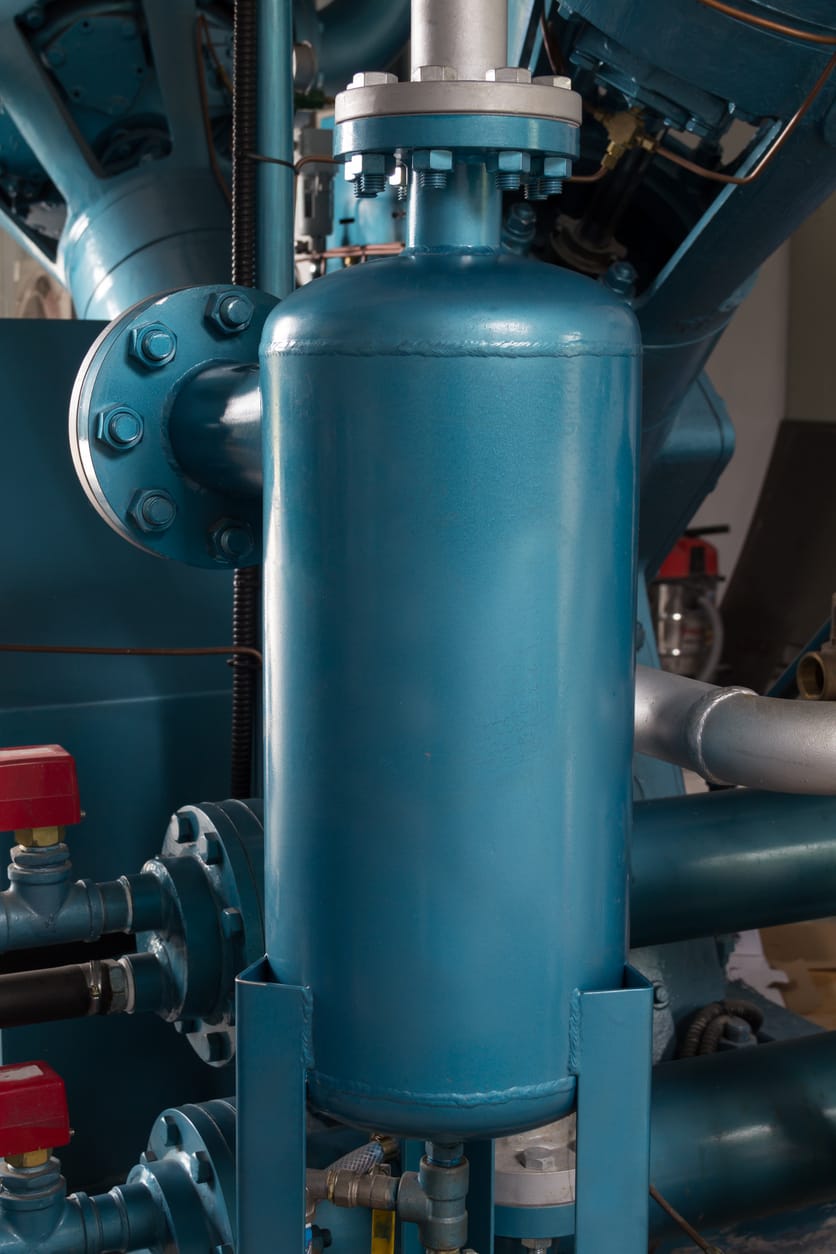

A common question among those who have attempted to relocate a vertical air compressor is whether or not they can lay it flat. This is because so many people worry about this.

Because of its height, weight, and bulky form, an upright air compressor is exceptionally difficult to relocate. Due to its size, transporting it requires adequate shipping expertise, thorough planning, and additional care to ensure its safe arrival at its destination.

Can I transport my vertical air compressor by placing it on the side?

The answer depends on the condition of the compressor you want to transport!

The process of laying down a brand-new air compressor when bringing it home from the store is often possible.

This is due to the fact that brand-new air compressors do not come with pre-installed compressor oil for lubrication purposes.

A used compressor that has been tipped on its side during transport may require maintenance after shipping. This is because used “oiled” air compressors will have moisture buildup in the tank.

The oil eventually makes its way to the base of the vertical air compressor tank. Even though there was supposed to be an intake filter, this old oil ended up in the compressor tank. If stale oil leaks into the valve at the air pump’s inlet, the compressor will be rendered inoperable.

-

See Whether Oil is Present

Before you can figure out how to move an air compressor, you’ll need to know if it requires oil for lubrication or if it is a brand-new compressor. Maintaining the compressor upright is especially important if oil is present in it.

-

Think about Using a Ramp

One of the simplest and most helpful methods is using a ramp. If you’re taking your air compressor on the road in the back of a pickup, for instance, you may use a hand truck to move it up and down the truck securely. However, you may not be able to use a hand truck to move your compressor if it is too large or if it is fixed to a pallet. Hiring a trailer may be the way to go.

-

Make Sure the Compressor is Setup Correctly

Whether you want to carry your compressor upright or lay it down on its side, you’ll want to secure it so that it doesn’t slide around during the journey.

Shipping a large vertical air compressor upright requires securing it to a pallet. For the duration of the trip, the compressor will remain in its proper location.

-

Dismantle It (Optional)

Taking the compressor’s head and pump off the storage tank is a safe way to lay it down for transport if you don’t want to risk oil spills. Even though you’ll still probably have to drain the oil before you move it, at least the pump will be in a more upright position for the duration of the process.

-

Using a Reputable Shipping Company

If you’re worried about being overwhelmed, a professional shipping company like SAC is an option to consider. After all, this may be the safest option for you.

With a dependable freight shipping company like SAC, you can rest certain that your vertical compressor will arrive safely and in one piece.

If you need to move your compressor, maybe you should check out SAC’s shipping services. We will quickly transport your item to its destination without sacrificing care for its contents, no matter how fragile it may be.

In deciding whether to transport your vertical compressor yourself or use SAC shipping company, you need to think about everything that might affect your decision. However, when it comes to moving unique commodities like air compressors, our shipping firm has the expertise you need.

Use the online calculator on our website to obtain a price right now. Alternatively, give Ship A Car a call (866) 452-3657 right away and speak with one of our support staff specialists.